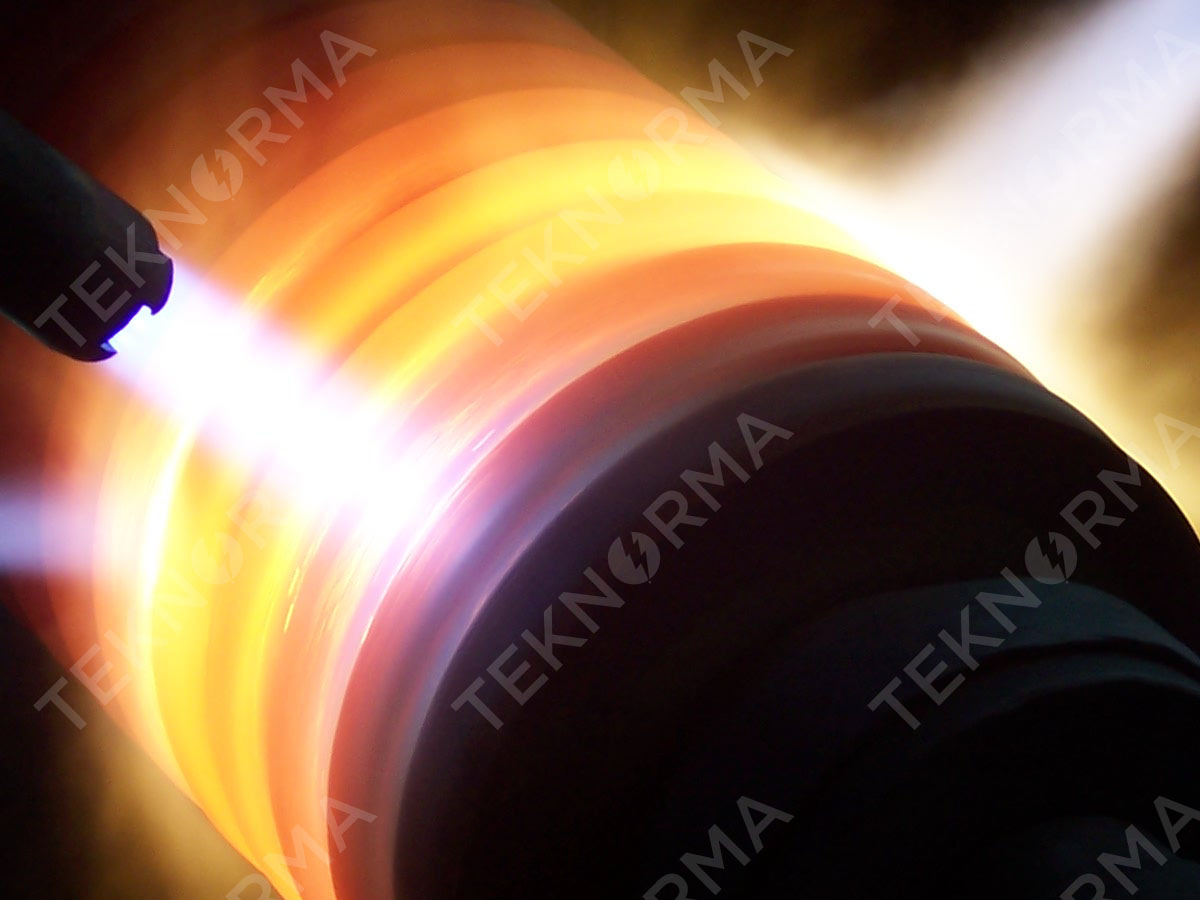

The basis of the coating process is the regular spraying of

thermal powder on the rotating workpiece with a flame powder spray system

followed by annealing and melting. This is referred to as the RW method. When the diffusion temperature of 1000 - 1100 °C is reached

with the help of annealing torches or induction current, the thermal powders

sprayed start to melt and adhere to the base material in such a way as to form

a metallurgical bond. As a result of this annealing, dense, tightly textured,

very good adhesion to the surface, as well as high operating temperature,

thermal shock resistant coatings are obtained.

In this coating method, nickel and cobalt based fusible

thermal powders are used. Ni Cr B Si and

CoNi Cr Mo Si B mixtures are frequently applied. Coatings exceeding 65 HRC

hardness value are obtained with tungsten carbide thermal powder compositions.

High annealing temperature may cause dimensional deformation

in parts. Therefore, this coating method is preferred for new productions.

Application thickness is max. 2 - 2,5 mm.

In the coating system called Eutolloy, thermal powders are

sprayed as melt from a special gun. With this system, which is suitable for

small surfaces, larger carbide hard coatings are made.

Wire drawing rollers and pulleys, transfer rollers, shower

table rollers, guide pulleys, pusher augers, mixer arms, wear plates, shafts,

pump sleeves, shafts and cams, tension rollers, scraper blades constitute the

application area.